The new issue of Loupe has landed.

Sign up to receive your FREE copy. Sign up

Loupe.

Discover in-the-know stories on watches (and watchmaking), plus articles on music, sport, art and culture.

Industrial evolution

For the 10th anniversary of Calibre SH21 – and the 20th of Christopher Ward – comes The Twelve X, the pinnacle of The Twelve Collection and a showcase for the misunderstood glories of machine finishing

Sunny delight

Enjoy the fleeting beauty of an English summer with a set of photographs that bring balmy days by the beach and boating lake to life

History boys

Christopher Ward co-founders Mike France and Peter Ellis talk about 20 years of CW: from the earliest days in a Berkshire chicken shed to a night of triumph in Geneva

Union tick

The British watch industry has grown over the last 20 years, but does it have a global presence? Laura McCreddie-Doak finds out

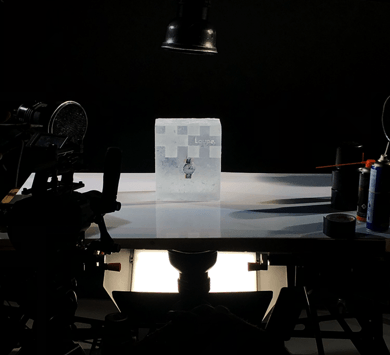

Sign up to Loupe magazine

Loupe is Christopher Ward’s quarterly in-house magazine. If you want to know what’s happening at CW (and you love great journalism), this is where to start. Alternatively, you can read all our back issues on your computer, tablet or phone.

Order your free copyRead Loupe online

We speak to Claude Greisler of Armin Strom about our collaboration on the C60 Apex.

Read online

Everyone loves military watches. Discover our collaboration with the UK Armed Forces.

Read online

The new C65 Anthropocene Limited Edition. C65 Black Gold and C60 Abyss.

Read online